Engineering Factory Automation

Call Us Today (262) 786-6570

Engineering

Turnkey Capability:

We specialize in offering complete “turnkey packages” for the machine tools we represent, including not only the program, fixture and cutting tools, but often the addition of automation, gauging with feedback, integration with existing equipment and the design and build of special purpose machines to be used within the manufacturing cell. Our in-house material handling equipment, adequate floor space and strong vendor relationships forged from years of experience in working as partners on turnkey projects provides State Machine Tool Co., Inc. the tools required to have successful run-offs in a timely basis. On larger projects requiring multiple machines, we provide within our quotations floor layouts of the equipment in both paper and CAD formats to assist the end-user in planning the plant area required to produce the parts.

Customer Profile:

Major Small Engine Manufacturer

Work Piece:

Twin Cylinder Engine Block

Scope:

Provide A & B fixtures, cutting tools, auto hydraulic clamping, program and run-off on our floor.

Install & Train.

Machine:

Seven (7) Toyoda FA450III HMC

Spindle 15,000Rpm with HSK63

Customer Profile:

Major Aluminum Die Caster

Work Piece:

Ford Water Pump Casting

Scope:

Provide Special Drilling Machine, Special Chucks & Jaws, Pallet Tooling for Part Conveyor System, Integrate 5 CNC Turning Centers to System, Program and Run-Off.

Machines:

5 Inverted Turning Centers & Special Drilling Machine

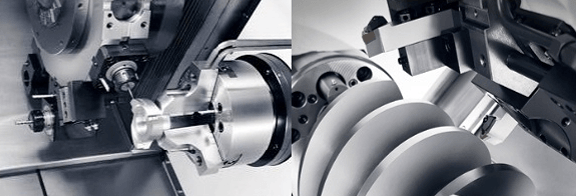

Automation

Integration:

State Machine Tool Co., Inc. offers enhancements to your machine tools to assist with increasing the productivity of your equipment by adding after market products not supplied by the original equipment manufacturer or to assist in automating of the equipment to run with minimal supervision or employees.

We offer these “integration packages” for all of the machine tools we represent and these packages can consist of but not limited to:

- Hydraulic Power Supplies & Software integration to the CNC Control

- Hydraulic Fixturing Integration with Confirmation Software

- Light Curtain Integration and Safety Software

- Renishaw Probe Installations and Probing Software

- High Pressure Coolant Systems – 1000 Psi or Higher

- Fanuc Robot Integration

- Magazine Barfeed Integration

- 4th Axis CNC Table Integration

State Machine Tool Co., Inc. • N56 W16743 Ridgewood Drive • Menomonee Falls, WI 53051

Toll Free:

800-727-8283 •

Local:

262-786-6570 •

Fax:

262-786-4185

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy

^